Quality Control

Get Bio Pak, state-of-the-art paper cup manufacturing facilities are equipped with cutting-edge technology and advanced machinery. Every step of the production process is closely monitored by our skilled technicians to guarantee precision and consistency in paper cup production.

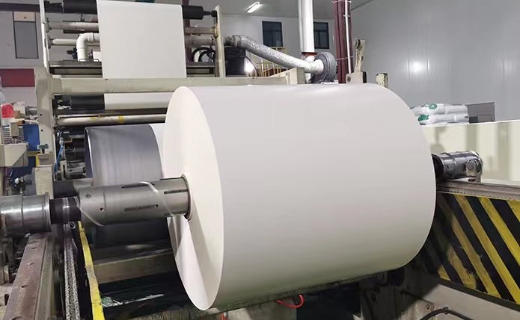

Materials? ONLY the Finest

The best paper cups are leak-free

We firmly believe that true premium quality can only be achieved through the perfect advanced machines and the finest materials.

When it comes to our paper cups, each material used is meticulously handpicked by our team of raw materials experts to guarantee not only top-quality but also a commitment to environmental sustainability.

At Get Bio Pak, paper cup production, we only use:

- FSC™ (FSC-A000523) certificate wooden pulp paper, high-quality paperboard

- Any sign of weakness, flimsiness, or poor construction should be picked out

- Each batch raw materials can be tracked for its resource

All paper cup materials will go through strict in-house inspections. Only qualified rae material paper will be put into mass production.

Our Process

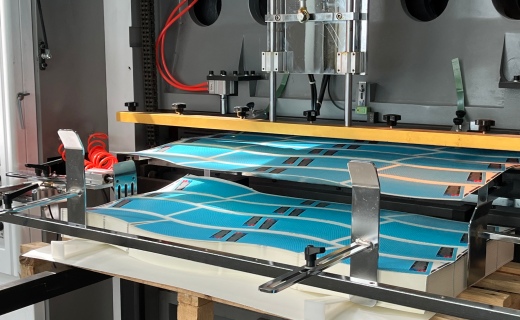

Auto-Machinery For Delicate Details

Coating

Water-based barrier applied to the surface of a paper cup to make it resistant to liquid penetration and leakage

Printing

The desired graphics, logos, or designs are created using graphic design software or by working with a professional graphic designer, MAX 6 colors

Shaping

The cup blanks are fed into a cup forming machine, which uses heat and pressure to sealing the cup blanks into a cylindrical form, speed 120 pieces/min

Testing

Cups are measured to ensure they meet the specified dimensions and capacity. checking the height, diameter, and volume of the cups, test within 18 hours

Packing

The carton packs facilitate the handling and transportation of paper cups. Sturdy and durable structural support to prevent from shifting or getting crushed during transit.

Our Time

Guarantee manufacturing & shipping time

Manufacturing time: 14 days

We do customized printing, cutting, forming the paper cup on high speed making machines, process with cup raw material inspection in advance

Loading time: 5 days

Well palleted or premium paperboard carton packed as per customer requirement, with soft loading into container, broken or fragile pick out

Packaging time: 5 days

We do carton packging when forming the paper cup on high speed making machines, process with shaped cups inspection during that

Shipping time: 15-30 days

We provide full set of custom clearance documents before you receive the vessel goods notification, get your goods from custom fruitly

Our Printing

Grow up Your Paper Cup Design Artwork

Printing File Format

Photoshop, Illustrator, CorelDraw Digital images CMYK (NOT RGB).

File formats .cdr, .psd, .eps or .ai

Resolution 300 dpi at least, dimensions up to 100%

A file should be created in a rectangular shape, prepared with curves in sizes relevant to the template;The gluing rim for the wrapper, logo or printed text should be considered.

Colors confirmation

Colors should correspond with CMYK or Pantone®.

The use of RGB colors is not recommended (if designs are in RGB colors, the final print quality may not satisfy the client’s expectations).

In files for purchase orders up to 50000 cups, Pantone® colours should be converted to CMYK.

Fonts

Conversion to curves – curves cover all font files

Target color – physical samples,Clients can courier us a sample printout piece.

The design should be printed on calibrated equipment.

The Single Use Plastic Directive (SUPD) FOR Europe Market

The Single Use Plastic Directive (SUPD) requires standard ‘Plastic in Product’ markings for beverage cups, regardless of plastic content levels. (See image for example of placement.)