Numbers Speak For Themselves!

1

Year Manufacturing experience

1

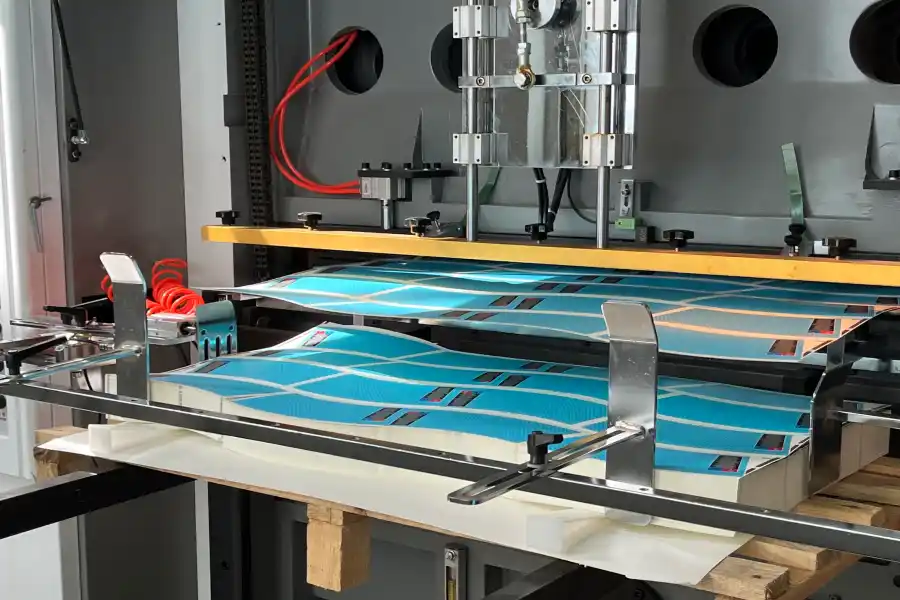

Machines

1

Employees

1

sqm

Factory & Distribution Centre

Factory & Distribution Centre